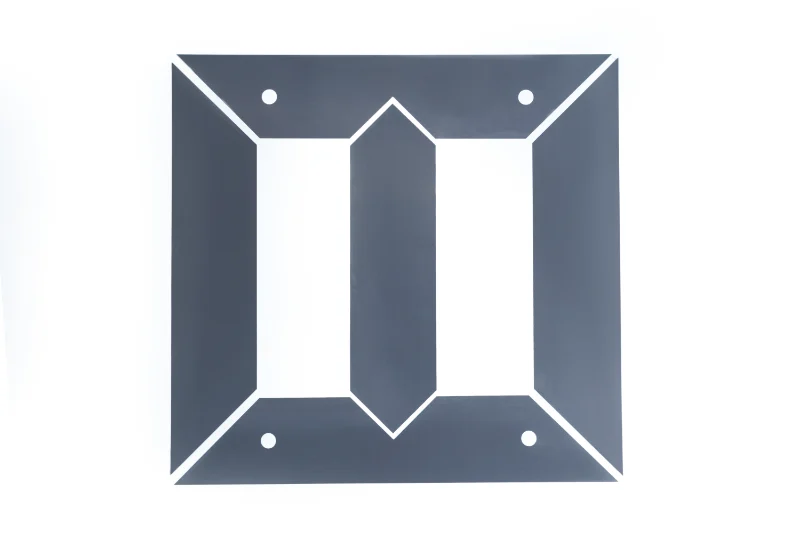

Fully machined rapid prototypes

Wuxi Aojin Hydraulic Machinery Co., Ltd. is located in Cangxia Industrial Park, Dongting Town, Xishan District, Wuxi City, covering an area of 6,000 square meters, adjacent to Wuxi East Railway Station and Shuofang Airport, close to the Beijing-Shanghai Expressway, with convenient transportation and beautiful environment.

Wuxi Aojin Hydraulic Machinery Co., Ltd. is located in Cangxia Industrial

Park, Dongting Town, Xishan District, Wuxi City, covering an area of 6,000

square meters, adjacent to Wuxi East Railway Station and Shuofang Airport, close

to the Beijing-Shanghai Expressway, with convenient transportation and beautiful

environment.

The company was founded in 2010, since its inception has been in the

automotive industry development, with many years of experience in cooperation

with domestic and foreign OEMs. The company has 100 employees, including 26

professional and technical personnel, equipped with Auto CAD, UG, Solid Works,

Pro-E and other software to assist in the design, but also equipped with three

coordinates, profilers, imaging instruments to monitor product quality. 2018 we

have obtained the IATF16949 quality system certificate, but also obtained 15

utility patents and 1 invention patent certificate. We have also obtained 15

utility patents and 1 invention patent certificate.

Subsequently, we will further improve the automation and intelligence of the

workshop and provide automation services for our customers to achieve win-win

cooperation In many years of cooperation with the automotive industry, we have

been committed to improving the technology forward-looking and quality

management level. The company now not only has a large-scale machining capacity,

but also has automation equipment and intelligent equipment design and

manufacturing capacity. We can provide extended services such as automation

inspection and assembly while providing machining services. Thanks to our rich

machining experience and development capability, our business has been expanded

to many industries such as automotive, military, home appliances and toys.

Features of Fully Machined Rapid Prototypes by Okin

Okin's Fully Machined Rapid Prototypes are designed to meet the dynamic demands of modern product development. These prototypes offer a range of benefits that set them apart in the competitive landscape of rapid prototyping services:

-

Speed and Efficiency: Our rapid prototypes are created using state-of-the-art CNC machining technology, ensuring that your product goes from concept to physical model in record time.

-

Precision and Accuracy: Every Fully Machined Rapid Prototype is manufactured to exact specifications, ensuring that the final product meets the highest standards of quality and performance.

-

Material Versatility: We offer a wide selection of materials for your prototypes, including metals, plastics, and composites, allowing you to choose the best material for your application.

-

Customization: At Okin, we understand that every project is unique. That's why our Fully Machined Rapid Prototypes are fully customizable to fit your specific needs and design requirements.

-

Cost-Effectiveness: By using CNC machining, we can offer high-quality prototypes at a fraction of the cost of traditional manufacturing methods.

Applications of Fully Machined Rapid Prototypes

Okin's Fully Machined Rapid Prototypes find application across a multitude of industries, providing solutions where quick turnaround and precision are paramount:

-

Automotive Industry: We create prototypes for new car components, helping manufacturers ensure their parts meet performance and safety standards before mass production.

-

Aerospace: Our prototypes are used in the development of aircraft components, where precision and strength are critical.

-

Consumer Electronics: In the fast-paced world of electronics, our rapid prototypes allow companies to quickly test new device designs and iterate based on feedback.

-

Medical Devices: Okin's prototypes are instrumental in the development of intricate medical equipment, where accuracy and reliability can mean the difference between life and death.

-

Toy Manufacturing: We help bring children's toys to life with detailed and durable prototypes that can withstand rigorous playtesting.

Okin's Exceptional Rapid Prototyping Service

At Okin, our commitment to excellence extends beyond the quality of our Fully Machined Rapid Prototypes. Our service is designed to provide you with a seamless experience from concept to completion:

-

Consultation: We work closely with you to understand your vision and provide guidance on the best approach for your prototype development.

-

Design and Engineering: Our team of skilled engineers and designers use advanced CAD software to translate your ideas into detailed digital models.

-

CNC Machining: Leveraging our CNC machinery, we meticulously craft your prototypes with precision and care, ensuring every detail is accurately represented.

-

Quality Assurance: Each Fully Machined Rapid Prototype undergoes rigorous quality control checks to guarantee it meets your expectations and industry standards.

-

Delivery and Support: Once your prototype is ready, we ensure it is delivered promptly. Our after-sales support is always available to assist with any further requirements or modifications.

okin is dedicated to providing the highest level of service in the industry. Our Fully Machined Rapid Prototypes are more than just products; they are the result of our commitment to innovation, quality, and customer satisfaction.

Reviews

There are no reviews yet.